HOW ARE CANNACHEWS MADE?

MADE IN THE USA

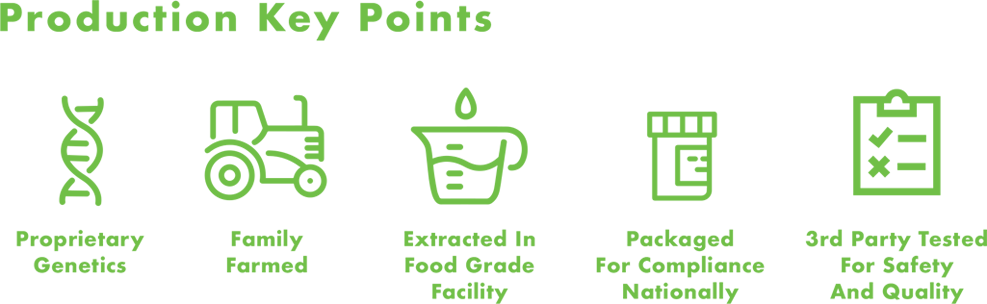

U.S. hemp farmers are seed to shelf CBD ingredient manufacturers, regulated under food-based extractions. These farmers operate under their state Departments of Agriculture in concord with section 7606 of the U.S. Farm Bill and the laws of their respective states. We source sustainably farmed premium CBD from the rich, fertile soils of the U.S. By leading agronomic and production research in industrial hemp the farmers we partner with develop and deploy novel hemp propagation and cultivation techniques that sustainably increase efficiencies and yields.

Our suppliers work with a team of scientists, geneticists, and botanists and cultivate innovative partnerships with state universities. The farmers we work with focus on techniques that reduce water usage and enable maximum soil health as the result of applied biologicals and nutrients. In addition to extending scientific advancements to the growing process, our suppliers work on applying scientific diligence throughout the production process. This culminates in all of our Broad Spectrum CBD being tested by leading third party laboratories to ensure safety and quality.

THE EXTRACTION PROCESS

Grow Pharmaceuticals utilizes the CO2 extraction process to turn raw cannabis plants into Broad Spectrum CBD suitable for use in CannaChews. The CO2 extraction process ensures that botanical extractions are pure, balanced and consistent from one batch to the next. The CO2 extraction method is widely recognized as the safest and most effective extraction method. It is a cold process that uses no solvents or toxins and does not contribute to the atmospheric CO2 levels. CO2 extraction involves filtering plants through a series of chambers that control temperature and pressure. When different temperatures and units of pressure are applied to cannabis plants, the sophisticated system is able to isolate CBD at a 90% efficiency. Then pressurized carbon dioxide is used to pull the desired chemical compound - CBD - from the plant matter.